In the worldwide transition from the use of fossil-based-energy to a more sustainable green-energy–infrastructure, electrolyzers that convert water into ‘green’ hydrogen are increasingly important. In this blog, PCS explains how dome-loaded back pressure regulators control hydrogen product streams across a broad pressure range and a broad flow range with very high accuracy.

Traditionally, hydrogen has always had a fossil origin. The most common way to produce hydrogen – even today – is based on “Steam Methane Reforming” (or SMR). Here, hydrogen is ‘released’ from natural gas, with the greenhouse gas carbon dioxide as an undesirable by-product.

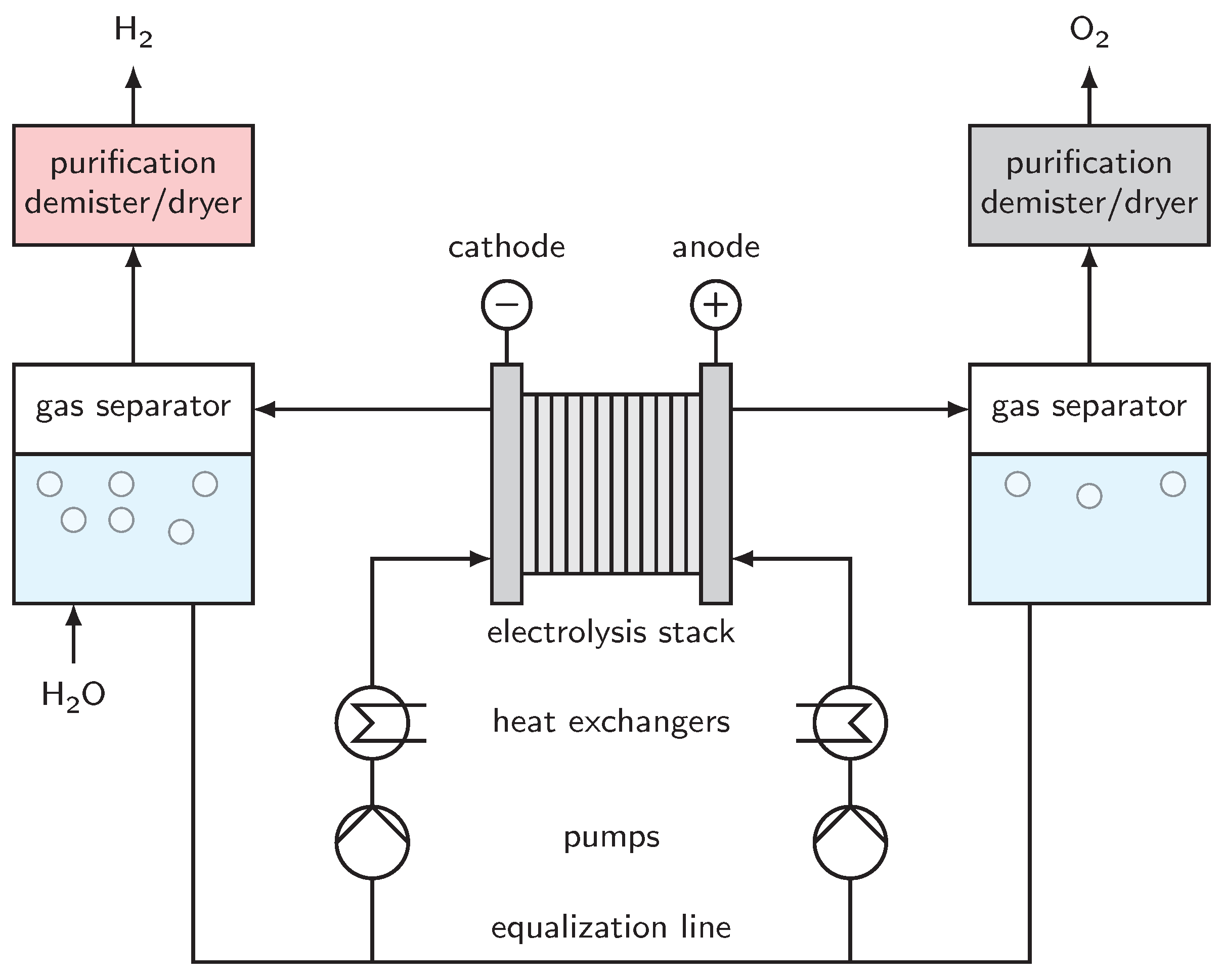

An ideal way to produce clean, green hydrogen is based on passing an electrical current through water, effectively splitting it into hydrogen and oxygen – a process commonly known as electrolysis. This hydrogen generation is even more green if the electrical current has a sustainable origin, such as solar-cell-based (PV) or wind-turbine-based current. Electrolysis is effectively a way to transform electrical energy into hydrogen as an energy carrier. This ‘power-to-gas’ can be used as long-term storage of electrical energy, or to use the hydrogen later as a clean fuel.

A practical design of such a water-splitting device is a polymer exchange membrane (PEM) electrolyzer. Water enters the device at one side as a continuous stream, and the electrical current allows hydrogen to selectively pass through the permeable membrane to the other side of the device. This effectively splits water into oxygen gas and hydrogen gas, which both leave the device at separate sides of the electrolyzer. Since hydrogen is often stored at high pressure after electrolysis, it is favourable to operate the electrolyzer also at high pressure. This will avoid any extra compression steps, reducing complexity and costs.

Constant pressure control of the continuous oxygen and hydrogen gas flows that are produced by the electrolyzer is a necessity. Especially the pressure difference between the two flows needs to be as small as possible to avoid any mechanical stress onto the electrolyzer membrane. And that’s quite a challenge at such high operating pressure. However, there is a solution: Equilibar dome-loaded back pressure regulators are ideal for these control purposes.

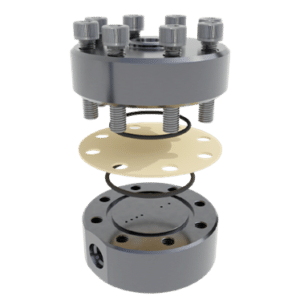

The trick of this instrument? By setting the pressure in the reference port, the pressure in the process port is controlled. This process port consists of a set of parallel orifices, covered and sealed by the diaphragm.

When the process pressure is larger than the reference pressure, this pressure difference lifts the diaphragm to release the overpressure. This diaphragm is the only moving part of the back pressure regulator.

This process channel of the regulator is located downstream of the electrolyzer, directly connected to one of the gas flows that leave the device. One back pressure regulator controls the hydrogen flow, and another one controls the oxygen flow. At a very low flow, only a small part of the diaphragm above one orifice is lifted to release the pressure. At a very high flow, the entire diaphragm above all orifices is lifted to release the pressure. This is essential for an electrolyzer application: at start-up and shut-down, the flow is high at ultra-low pressure, whereas during ‘normal’ operation the pressure is high with an ultra-low flow. This results in a very wide flow range, with a rangeability of 1000:1 or even larger.

In this application, we are dealing with gases (hydrogen and oxygen) and a liquid (water). At the same side of the electrolyzer where water is introduced, oxygen bubbles are formed, giving rise to a liquid/gas two-phase flow. Fortunately, the multiple orifices of the dome-loaded back pressure regulator allow controlling the pressure of the oxygen flow in the presence of water. While a few of the orifices may be flooded with liquid, the remaining open orifices are still able to transport gas and, hence, release pressure. The gas simply chooses another path than the liquid. During normal operation, two-phase-flow is to be avoided. The capability of the back pressure regulator to do just that directly adds to the robustness of the system and its suitability for electrolysis applications.

Although the electrolyzer can be operated at high total pressure, say 50 bar, the pressure difference between the oxygen side and the hydrogen side needs to be in a range of 10-100 mbar, depending on the type of electrolyzer. This is the maximum pressure difference that the electrolyzer membrane can handle. This high precision – 50 mbar in relation to 50 bar operating pressure – requires a control precision of <0.1%, which is a huge challenge for traditional valves, often even impossible. Dome-loaded back pressure regulators are capable of handling this high precision, by controlling the process pressure by a reference pressure. To manage this, the reference ports of the regulators at the oxygen-side and the hydrogen-side need to be interconnected, as can be seen in the image below.

For electrolyzers operating at 40 – 60 °C, requiring a design temperature of 120 °C, the Equilibar back pressure regulator is a good match, as its constituent materials can withstand such higher temperatures. Moreover, as oxygen poses the risk of self-ignition at high concentrations, the robust regulator can be built of several chemically inert materials that can cope with these conditions, such as Monel or brass. The diaphragm can be made out of PEEK, SS316, or Hastelloy.

The characteristics of the Equilibar dome-loaded back pressure regulator show: This instrument is the ideal choice for pressure control in electrolysis systems. Contact us today to learn more or to discuss your application with our Application Engineers!