The Norwegian Petroleum and Process Technology group – part of the Department of Physics and Technology, University of Bergen – focuses on research and experiments in the area of carbon capture utilization and storage, enhanced oil recovery and hydrates. Within this area of research, experiments around high pressure CO2 -injection for enhanced oil recovery (EOR) play a significant role.

Already since 2014, they make use of Equilibar ZF Series (Zero Flow) back pressure regulators in these experiment set-ups. They run a total of 5 experiment setups that include our smart, high precision pressure control valves, built to include Equilibar’s patented dome-loaded diaphragm sealed technology. Safe to say that they were among the early adopters of our innovative products in Europe! Meanwhile, this research has progressed steadily – the list of scientific publications (at the bottom of this page) stemming from the Reservoir Physics group speaks for itself.

In this application blog, we ask Marianne Steinsbø, Senior Engineer of University of Bergen, how our precision pressure control products have made an impact on this research group’s research projects in the past 7 years.

As part of the research into carbon capture utilization and storage, enhanced oil recovery and hydrates, experiments need to be conducted around high-pressure CO2-injection for enhanced oil recovery. These experiments are executed to investigate rock samples and micro models under high temperature and high pressure, in order to further explore the utilization and storage of the climate gas CO2 and formation of hydrates during CO2 storage. This is done for the purpose of furthering injection strategies for enhanced oil recovery in mature oil fields.

As often is the case with experimental research, controlling the process parameters is key to reliable and repeatable research. For the Reservoir Physics research, high temperature and high-pressure control is one of those key elements. Their first experiments making use of Equilibar back pressure regulators are presented in Steinsbø et al., 2015. Currently, almost all their CCUS-injection-experiments include an Equilibar control valve.

Marianne Steinsbø describes the requirements of her research application as follows:

“During these experiments, we need to measure the pressure drop in core systems with pore volumes of 25-150 ml. Desired trends that should be observed are in the range of small pressures changes of 0,1 bar, small volume changes of 0,5 ml or changes over a certain timeframe (10 min). It is essential for the experiments that the back pressure regulator – that is placed downstream of the process (as can be seen in the figure) – releases fluid evenly for accurate results.”

As Marianne further explained to us, a typical experiment lasts 4 to 5 days. During this time, the experiment goes through different phases, starting with a test and initial pressurization of the core sample (day 1), continuing with drainage of the core sample with crude and mineral oil (day 2), waterflood of the core sample (day 3) and finally the CO2/CO2 foam injection (day 4 and 5). During this timeframe, the back pressure regulator is set to maintain a constant pressure, ranging from 90 to 180 barg. Across these experiment phases, the flows vary strongly: Although the flow will be between 1-5 ml/h generally, at initialization the flows can reach as high as 200 ml/h for up to 1 hour and in the draining phase, the flows can even reach 1 l/h. Summarizing, the whole experiment requires a rangeability of 1:2.000!

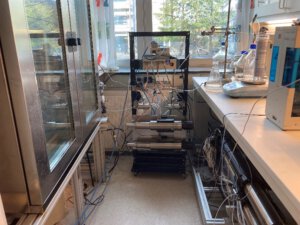

In figure 1, we see the research set-up for the injection of (supercritical) CO2 into the core under test. CO2 and decane are led into the core with an aqueous solution at elevated pressures up to 400 bar and temperatures up to 120 C°. In other experiments, other media like isopropyl alcohol may also be used. The BPR is placed downstream of the core to keep the pressure in stable during the test. The process side of the Equilibar regulator will be in contact with both water and CO2 (or other media), while the reference pressure is set using nitrogen.

The Equilibar regulators are placed outside of the heating box, but will still be in contact with the hot media. This picture shows the heating box, with the Equilibar valves right next to them, also visible in the close-up.

The research lab further utilizes a separate, smaller sized Equilibar back pressure regulator that is mounted to the wall for easy access and operation, thus allowing for flexibility and ease-of-use in the planning and execution of smaller experiments.

When we asked Marianne Steinsbø to explain what the use of Equilibar back pressure regulators has meant for her research in terms of usability and reliability, she is very open about the advantages her research group experienced:

“Over the years, we identified several advantages of the ZF back pressure regulator, comparing it to other conventional back pressure regulators that we knew:

- No hydrate formation in the regulator due to pressure or temperature drop

- Fluid is released evenly, without pressure fluctuations

- Good compatibility with our 2- or 3-phase flow process (gaseous, liquid and supercritical CO2 )

- Easy to clean the regulator after gypsum clogs from process”

The advantages that Steinsbø testifies to have been confirmed by many other researchers who use our innovative, patented back pressure technology and/or electronic solutions for precision control of process parameters. See for example also this blog about ultra low flow control and read more about the BR Series, that is particularly designed to be blockage resistant for use with supercritical CO2.

If you wish to discuss the characteristics of your application and want to explore our capabilities for solving also your particular pressure challenge, please contact our engineers today! They always welcome a new challenge and are happy to share their expertise with you.

Read more about the research by Marianne Steinsbø in the Publication List.