The process of core flooding is typically performed in the oil and gas industry to determine the various intrinsic properties of a rock sample. These include, but are not limited to, permeability, saturation, formation damage, and hydrocarbon content. The fluid that is injected into the sample usually consists of different liquids and gases, such as methane, carbon dioxide, brine, and oil. Other fluids such as acids, foam, or other chemicals may also be used.

Core flooding can be performed under a wide variety of parameters, which can range from very low pressures and ambient temperatures to pressures of several hundred bars (sometimes even several thousand bars) and high temperatures of up to 200 °C. Also, the flow rate can vary widely in the process of analyzing cores. The flow rate often needs to be truly zero, while at other times in the process several hundreds ml/min can be achieved or may be required.

What becomes clear from the aforementioned parameters and conditions, is that the Cv requirements of this process may have a very broad range and that several corrosive or caustic substances may be used. As a consequence of these broad Cv ranges, it can be challenging to assure that the pressure inside the system is kept in a precise way, especially at zero flow. Furthermore, conventional back pressure regulators cannot handle the large differences between the minimum and maximum flow and Cv. Also, the chemical compatibility of materials can be an issue for these regulators.

To assure the pressure inside the core flooding system with sufficient precision, the Equilibar Zero Flow regulators and Ultra Low Flow Series (UxL) – both part of the Research Series – are an optimal fit. Because these are designed as a dome-loaded pressure regulator with a flexible, sensing diaphragm, it has no hysteresis, which ensures very high precision in controlling pressure at zero or low flow.

The characteristics of Equilibar back pressure regulators in the Research Series will not only solve the challenge of precise pressure control at zero flow, but also the aforementioned problems that conventional back pressure regulators have:

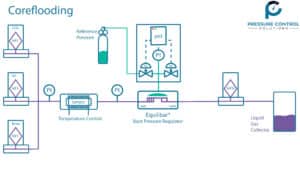

In our P&ID schematic below, CO2, brine and oil are fed into the core using mass flow controllers (MFC). As mentioned, the composition of the fluids that are fed into the core can strongly vary. Downstream of the sample, an Equilibar® dome loaded back pressure regulator is placed in combination with a dual valve electronic pressure controller to keep the pressure stable in the sample compartment. In this case, the reference pressure is set in a 1:1 ratio with the desired upstream pressure. The reference pressure (also called: pilot pressure) is controlled electronically in our example, but could also be set with a manual forward pressure reducing regulator. A core flooding set-up is usually equipped with pressure gauges or transmitters (PT) to monitor the pressure but is also often equipped with mass flow meters (MFM) and liquid/gas separators. If you want to learn how to pilot your back pressure regulator, click on this link for further information.

You may also be interested in this Pore pressure transmission case study by Equilibar and the University of Aberdeen Petroleum and Natural Gas Engineering Research Group.

If you want to learn more about our products for use in core flooding applications, please do not hesitate to contact us. We are happy to advise you to help you maximize the performance of your system.